We have used boron nitride spray for all the molds in our studio for many years. My favorite type is the kind that comes in a convenient spray can (like spray paint). It works fabulously on ceramic molds for slumping, draping glass and casting glass. I have heard all the reasons why some fusers don’t like it but I have found that these objections are usually from people who have either never used boron nitrite or used it incorrectly and had a bad result. So let me explain why I love boron nitrite for all my studio molds.

But Boron Nitrite is so Expensive

The biggest objection I hear from crafters about boron nitride mold release is “it’s so expensive”. I know what you’re saying, a can of boron nitrate could be $49 and that is a lot of money. However, once you have witnessed the superior results and discover just with how far a can goes, the cost turns out to be quite reasonable. Let me give you an example of what I’m talking about.

A Silky Smooth Glass Surface

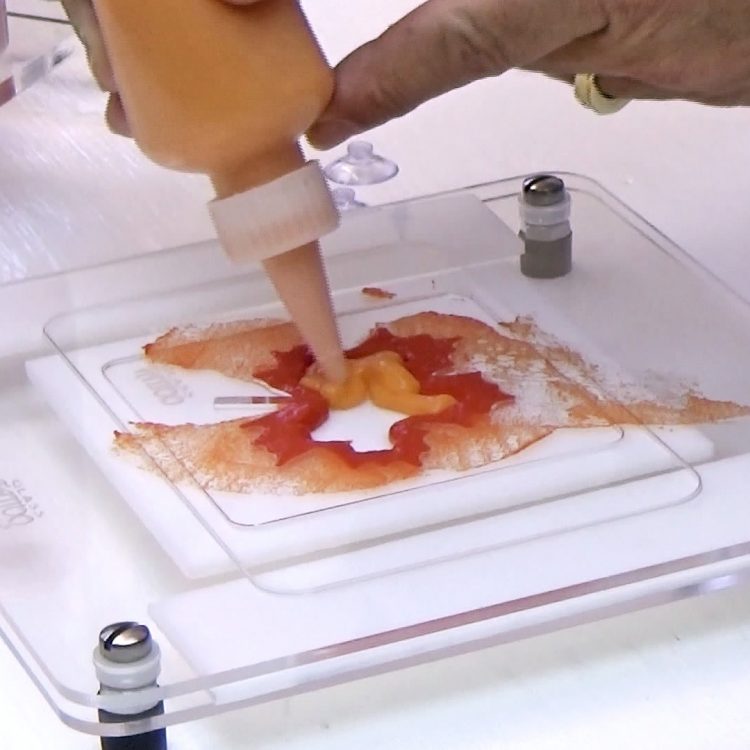

Our most popular fusing mold is the M35 Starfire drape mold. The image that we often use to show what you can do with that mold is the Hot Fritage Bowl (shown below). You wouldn’t believe how many emails I get asking me how I got the interior of that bowl to be so clear and smooth. The answer is simple, you have to start with a very smooth surface on the mold then you have to use boron nitride spray as the mold release. No matter how carefully you apply kiln wash to a mold, you will never get it as smooth as a sprayed-on application of boron nitrite, it’s just not possible. When glass is heated to slumping or draping temperatures it takes on every little bump, groove or mark that it comes in contact with and that includes brush marks in kiln wash.

Shiny and Clear, Inside and Out

My desire is to try and make my fused glass pieces look as much like hand-blown glass as possible. That means all surfaces need to be as shiny and clear as I can get them. Of course as I mentioned, hot glass takes on every little imperfection that it touches and even with a layer of boron nitrite, the glass is still touching the mold so there will always be some amount of surface texture transferred to the glass. By using boron nitrite that texture is minimized and the glass surface does have a semi-gloss shine to it.

Costs Less Than 70 Cents Per Firing

I also mentioned that a can of boron nitrite goes a long way. When I am preparing a new mold with boron nitrite, I apply 3 very light and uniform coats. You want to avoid having any irregular thick and thin areas. The goal is to cover the entire surface of the mold with a consistent boron nitrite skin. This initial treatment will be dry and ready to use within 10 minutes. After the first firing, your mold can be reused with only one quick touch-up coat. I estimate that I get 65 to 75 coats from a 13oz can. Do the math to discover that a 13oz can at $49 costs approximately .70 cents per firing. That is literally a fraction of the cost for all the other materials that I have invested in my fused glass piece that I am about to put on a shaping mold.

Recycle, Reuse and Refire

Some fusers have told me that they will refire a mold treated with boron nitrite 2 or even 3 times before applying a touch-up coat. That may be possible, but I would not try that myself and let me tell you why. I put a lot of time into creating my fused design pieces, add to that the cost of the glass and other decorative materials plus at least one (or more) flat design kiln firings. When I have a successful fused glass design piece completed and I’m at the final step to shape it on a mold, I am not willing to risk using a mold that I am not absolutely sure has a proper coating of release, particularly when the most I will be saving is .70 cents – it just doesn’t make any sense (see what I did there?).

If you have used a Boron Nitrite Mold Release, please leave a comment below with your experience. Be sure to mention the brand name of the product that you used.

31 Responses

I have used ZYP and it is more expensive so I am going to give Mo Re a try. It was told you could not use the spray on your molds and when I read up on it you can so I tried it and it is the best there is Kiln wash takes a long time putting a coat on then let it dry and back and forth and kiln was is messy. I love the spray it is easy and everything comes out excellent. I agree with Randy, The cost in minimal and why take the chance of ruining your piece. I have ruined a mold in the past so I would rather give it a quick spray the ruin an expensive mold or worse ruin my expensive glass piece.Thanks Randy! It’s a good article and worth saving the money.

Thanks for the positive comment.

I mostly use Zyp spray, but will give the MoRe a try. The only time I have found it absolutely necessary to use kiln wash is for Wissmach luminecent. For whatever reason, the luminescent just seems to ‘stay’ better with kiln wash. But perhaps it is something with the Zyp…I will retry my experiments with the MoRe and see what happens. Can you apply the MoRe over a mold coated with Zyp?

The nozzle has stopped up several. I turn the can upside down after spraying to clear the nozzle and I have cleaned it with a toothpick. I am now just starting to fire because the weather is cooler so I will see if my spray works. It is frustrating to have a full can that won’t spray. JoC

Thanks for your comment Sheri. ZYP and MoRe are very similar, I don’t think you would find a different result as it relates to Wissmach luminescent. I agree with you, luminescent does seem to burn out more when fired on Boron Nitrite. I have had the best success by firing my flat design panels on Papyros kiln shelf paper by placing the luminescent side down, so that side is in contact with the paper. Some of the luminescent still is lost but enough is held to make a beautiful result plus this seems to make the luminescent more stable. Then I can shape fire my design panel on a mold coated with MoRe (or ZYP) and the luminescent remains mostly intact. Of course the amount of luminescent that remains varies from piece to piece but that is the my process that seems to give me the most success. BTW: we sell Papyros kiln shelf paper on our website.

The answer to your question, Can you apply the MoRe over a mold coated with ZYP? Yes you can and you can switch back to ZYP after MoRe. They both contain Boron Nitrite, the main difference is the propellant used to aerosolize the Boron Nitrite. ZYP uses a flammable propellant while MoRe is non-flammable and can therefore be shipped as a non-hazardous product.

You can apply Boron Nitrite over a mold that was previously coated with kiln wash. Simply use a very fine sandpaper (400 to 600 grit) to make the mold surface smooth as possible, then apply MoRe as if it were a new mold. HOWEVER you need to be aware that once you have applied Boron Nitrite to a mold you cannot go back to kiln wash. Boron Nitrite is so slippery that kiln wash will not stick to the mold.

Hi JoEllen: A clogged nozzle is frustrating. I had that happen to me with a can I got a couple of years ago. I sent an email to the manufacturer and they sent me a new can. I suggest you take a photo of the can then email it to the manufacturer, I suspect they will have a solution for you.

Hi Cheryl, thanks for commenting on my blog. Your question about the difference between a ZYP aerosol and ZYP liquid in a bottle with a pump sprayer is a good one. I have used both and I find that the ZYP aerosol gives me a much finer spray and as a result the coating is smoother, which I prefer because it leaves the bottom side of my slumped pieces much smoother as well. That being said I have used the ZYP liquid in a bottle on both slump and drape molds and it seems to function quite well. However, I have not tried using the ZYP liquid with a casting mold and to be honest I wouldn’t recommend it because if it does not work and you lose a casting mold it’s just not worth the minimal savings between those two types of ZYP coatings. If anyone out there has tried the ZYP liquid in a casting mold please drop us a comment to let us know how it worked out.

Finally, I have to admit I have never tried applying the ZYP liquid using an airbrush and a compressor, if you do give that a try please let me know your results, I’ll be very interested.

Hi everyone, is it possible to use ZYP Boron nitride spray or aerosol on ceramic moulds for glass slumping and fusing?

I’m a newbie and totally lost!!

Any advice would be amazing 🙂

Thanks, Annie

I have not seen any info on cleaning a mold after firing with boron. I have used ZYP with great success but do I just wipe it off, dry, and spray again? Long time stained glass artist but new to hot glass…

Hi Cheri: I love boron nitrite spray and use it on all my molds. You don’t have to clean it off as you would with kiln wash/primer. Just a light brushing with a soft bench brush to clear away the loose dust and that’s it – You’re ready to give the mold one light coat (be sure to cover all areas of the mold) then fire it again. Hope this helps. Randy

I have been fusing for only a year. I use nothing else on my molds but ZYP and have had NO bad experiences. One mold (butter dish top) I tried to use kiln wash instead to see the difference. I painted on five layers of wash going in each direction, letting each layer dry first. I put in my glass and fired. It looked great until I tried to remove the glass, it stuck!! I ended up having to break the mold (so much for a $39 mold!) to get the glass out. Fusing Failure 101! From that experience, I have used nothing but ZYP!

Hi Annie: Since you left this comment on my blog article titled “Everything You Need To Know About Boron Nitrite Mold Release” I assume that you noticed that I talk quite a bit about using Boron Nitrite on ceramic molds – and I love the ZYP brand the best.

I use ZYP on my molds. I have put on 5-6 coats and I have had several things stick. Is it the temperature I am using 1500 or something else.

Hi JoEllen. Thanks for your question. If glass is sticking to your mold there is only 1 reason that happens – there was not enough ZYP on the area where the glass stuck.

There are 2 possible ways that can happen. First it is absolutely necessary to vigorously shake the can for one full minute before using the ZYP spray. Let me warn you, one full minute will seem like an eternity while you’re shaking, so I always set a countdown timer on my phone to make sure I do it for one minute. The reason you need to do this is because the boron nitrite settles in the can and MUST be completely mixed with the propellant, otherwise you may think you’re spraying properly but only a very thin coat of ZYP will actually hit the mold and that will create bald spots on the mold where the glass will stick. So lets assume you did shake the can for one full minute then sprayed the mold with 2 coats (5 to 6 coats is WAY TOO many). The only other possibility is you are not spraying evenly and therefore the ZYP is missing (or too thin) in some areas.

Those are the only 2 possibilities. If the ZYP is well mixed and the mold is evenly coated, the glass will not stick at any temperature under 1600°F

Hope this helps

Randy (The Fuse Whisperer)

I have a dragonfly mold that has little lines separating the wings. After firing the MR 97 I used is leaving a residue just in those small indentions. Is there a reason why?

Hi Lori, I am not sure what you mean by “leaving a residue” If you’re talking about a fine white powder “residue”, that is nothing more than the boron nitrite after it has been fired. Simply use a soft bench brush to brush away any loose powder that is still inside the mold, then spray it again with the boron nitrate spray and your mold is ready to go for your next firing. However if the residue you are referring to is some of the powdered glass that you used to create the dragonfly wings, and if that powder Glass is stuck to the mold, that would indicate the surface of the mold was not adequately covered with the boron nitrite enabling the glass to stick to the ceramic mold. If you’re lucky and not too much glass powder is stuck, you might be able to use some fine sandpaper to grind away those areas where the powdered glass is stuck, then you can spray the mold once again with a nice even coating of the boron nitrate spray and the mold would be ready to go for your next firing. Hope this helps, Randy

I used MK Impex Corp’s Boron Nitride spray on a ceramic jewelry mold for a fused glass project. The glass released great, but there was a white coating on the glass where it came into contact with the mold. I have tried several chemical solutions to remove it as well as a brass brush and sand paper with limited success. Can you shed some light on this?

Thank you for the great information on ZYP use. I have been a fused glass artist for many years, but have never used boron nitrate. I have a metal wave mold, and I sprayed it with a few thin coats of boron nitrate. It worked great! Can you tell me if it needs to be reapplied every time I slump on it, like with a ceramic molds? I also noticed the fine powder, do I just wipe that off after each use?

Thanks again!

Randy: I do a lot of fused glass art so I use a lot of molds. I use ZYP spray or aerosol on these molds. My husband is always looking for fused glass and accessories at garage sales, etc for me. He got this big bag of BN Powder ZG at some sale or auction thinking I might be able to use it. I’ve had it for awhile and when I was getting close to running out of the ZYP spray I looked at this big bag of powder and wondered if I can use it on my molds by mixing it with water or something like that. Can you help? Thank you.

Hi Anita: I am not familiar with MK Impex Corp’s Boron Nitride spray so I can’t comment on that product specifically. However I know there are many varieties of BN spray created for industrial uses well beyond fused glass. I suspect the one you mentioned has a different formula that the 2 I am familiar with (ZYP and MORE) and may have some type of adhesive added to it so it will stick to whatever surface that product was developed and intended to be used on. As for what can you use to remove the white coating, the only solution I have heard that may work (and I have not tried it myself) is CLR. Apparently soaking your glass in a stiff mix of CLR (something like 50% CLR / 50% water) for 48 hours (or even longer) then scrubbing it with a wire brush will remove more of the residue. The only other option is to sandblast the surface to remove the BN residue and then enjoy the mat back (call it a creative solution). Then don’t use that BN again.

Hope this helps

Randy – The fuse Whisperer

Hi Kimberly: Glad your project turned out using the BN spray on a SS mold. The best way to get rid of the white powder left after a firing is to simply shake it off (if you brush it off, it will remove too much of the BN spray). Then ALWAYS spray the mold with one coat of BN before using it again. There is a possibility that you could use it a 2nd time without spraying, but since it only costs 50 cents to spray the mold – why risk it? The glass and time you can put into the project is way too expensive to take that kind of risk.

Hope this helps

Randy – The fuse Whisperer

Hi Donna: I am not familiar with the Boron Nitride Powder ZG that you mention, but I have used BN powder a long time ago. It does work but it is a pain in the you know what to apply it to a mold (as compared to a BN spray). If you want to give it a try you can mix it with water or better yet rubbing alcohol. The alcohol will evaporate much faster than water giving ou a better chance of having it stick o your mold. The problem with any BN liquid application (you can buy it in a liquid form now) is it wants to run downhill, so apply it to an 3D mold means the top section will not be as well coated as the lower sections. As I always say, you must weight the the cost of the glass and the time you spend to create and fire your design piece, against the savings of any alternate coating. Because we know the ZYP and MORE spray works and if this powder sticks to your glass and ruins your project, that will not be a satisfactory outcome.

PS: See my answer to Kimberly Lopez below.

Hope this helps

Randy – The fuse Whisperer

Is there an efficient way to remove mold release from a casting or impression mold without wearing down the features of the mold I currently use a stiff scrub brush like dishwashers use until no clouds of boron are evident. Is there a better way to preserve mold integrity?

I have been using ZYP BN brushable for a little while, but I find that on my metal molds, when I drape there is always a thin line layer of boron sticking to the glass that I cant seem to get off. Tried reducing the amount of BN I put on the mold and it helped a bit but still does not come off even with rigorous scrubbing. Is there a type of boron nitride that works best for not sticking to glass from metal molds?

Hi Jackson

You mentioned that you are using the ZYP BN brushable product. Unfortunately I think that is the answer to your question. It is very difficult to get the brushable product on any kind of mold with a consistently thin layer and even more difficult to get it on a stainless steel mold in a thin smooth layer. Any thicker areas of boron nitrate has a tendency to stick to the bottom of the glass. That is why the only product that I recommend using on a stainless steel mold, or for any kind of mold for that matter, is ZYP boron nitrate spray. This stuff goes on very easily and only requires a couple of thin coats on a stainless steel mold for perfect results. I have never had the ZYP spray boron nitrate stick to the bottom of my glass during a slump or drape firing. I do use the ZYP boron nitrate brushable product on some of my kiln shelves, but I never fire directly on top of the brushable product, I always put one thin layer of ZYP spray on top of the brushable product and I do not get any sticking even at fusing temperatures.

Unfortunately I do not have a solution for you to remove the ZYP brush on product that has already stuck to the bottom of your glass. I know that it can be removed by sandblasting the bottom surface, but then you have a sandblasted surface to deal with. You could fire it again to fire polish that surface, but it will not go away completely since that surface will still be touching the stainless steel mold with the ZYP spray on its surface.

Hope this helps

Randy (The Fuse Whisperer)

Wardell Products

randy@artglasslove

Hi Ronald

I am not sure why you are working so hard to remove a boron nitrate mold release from your casting or slumping molds? To be honest I almost never wash the boron nitrate off of my molds, even the ones that have fine texture details. If you feel that you need to remove the boron nitrate, I suspect you might be putting it on too thick in the first place. Are you using the ZYP brushable boron nitrate? If you are that’s the answer to your question. I always use the ZYP spray boron nitrate on my mold because that give me a consistent even coating of boron nitrate. The layer is thin enough that I don’t have to remove the boron nitrate after a firing. All I do is use a soft bench brush to brush away any loose powdery boron nitrate, then spray the mold one more time and it’s ready to go. The big advantage to this method is you’re not removing the boron nitrate completely from the mold and it only requires a couple of quick spray coatings to give an efficient coating. This greatly reduces the amount of spray boron nitrate I have to use, saving me money in the long run.

Hope this helps

Randy (The Fuse Whisperer)

Wardell Products

Mobile: 954-557-5589

randy@artglasslove

If I want to use powdered BN and mix my own spray, do you know mix ratios?

Hi Tom:

It has been many years since I used powdered Boron Nitrite and I do not remember s what ratio I used. I do remember that one of the issues of mixing and applying you’re own mix of BN, is it has a problem sticking to non-porous surfaces. We used to use it on stainless steel molds and I remember having to put the stainless steel mold in the kiln and heat it up to 150° or so, then quickly apply the boron nitrate mix ed with water to the hot mold and it would dry quickly and stick before getting runs. I do remember that it wasn’t always successful and didn’t always stick the way I would like it to. To be honest I never really perfected that technique on, I suspect there must be a way to add something to the mixture that would allow it to stick and dry better than my experience. I wish I could give you more advice but that’s all I know about the powdered boron nitrate.

I only use the spray nozzle ZYP since where I live there ar no hot glass shops near by, and thus have to have it shipped. I have nevr had a problem with it in casting molds, but I also move the spray bottle like I would an aerosol can so it doesn’t puddle. That is the ONLY issue I’ve ever had with ZYP– an occasional drip mark if I spray too much in one place at a time. I’ve never bothered with an airbrush or compressor, I don’t do enough to make that worth it, though I am very careful to clean out the pump sprayer every single time 100% and recap the bottle both to avoid clogging and loss due to evaporation so I would say I get closer to 50 coats a bottle if that.

Sadly, I HAVE lost casting molds to Slide (which is the only brand of aerosol I can get locally), not sure what exactly went wrong, the post on a holely mold ended up breaking off and then it’s replacement the glass just stuck in patches all over. So I wouldn’t say that all boron nitrite is equal…

I have a bunch of slumping molds that appear to be coated with something. How do I know if it’s kiln wash or Zyp?

Thanks in advance

Hi John, it’s really quite easy to determine if those molds are coated with kiln wash or boron nitrate. Run your index finger across the surface of one of the molds and you should have a white powder on that finger. Now rub that index finger against your thumb and if it feels really slippery that means it is boron nitrate (ZYP). However if the powder on your finger feels a little gritty that will tell you it’s kiln wash.

Hope this helps, Randy