Description

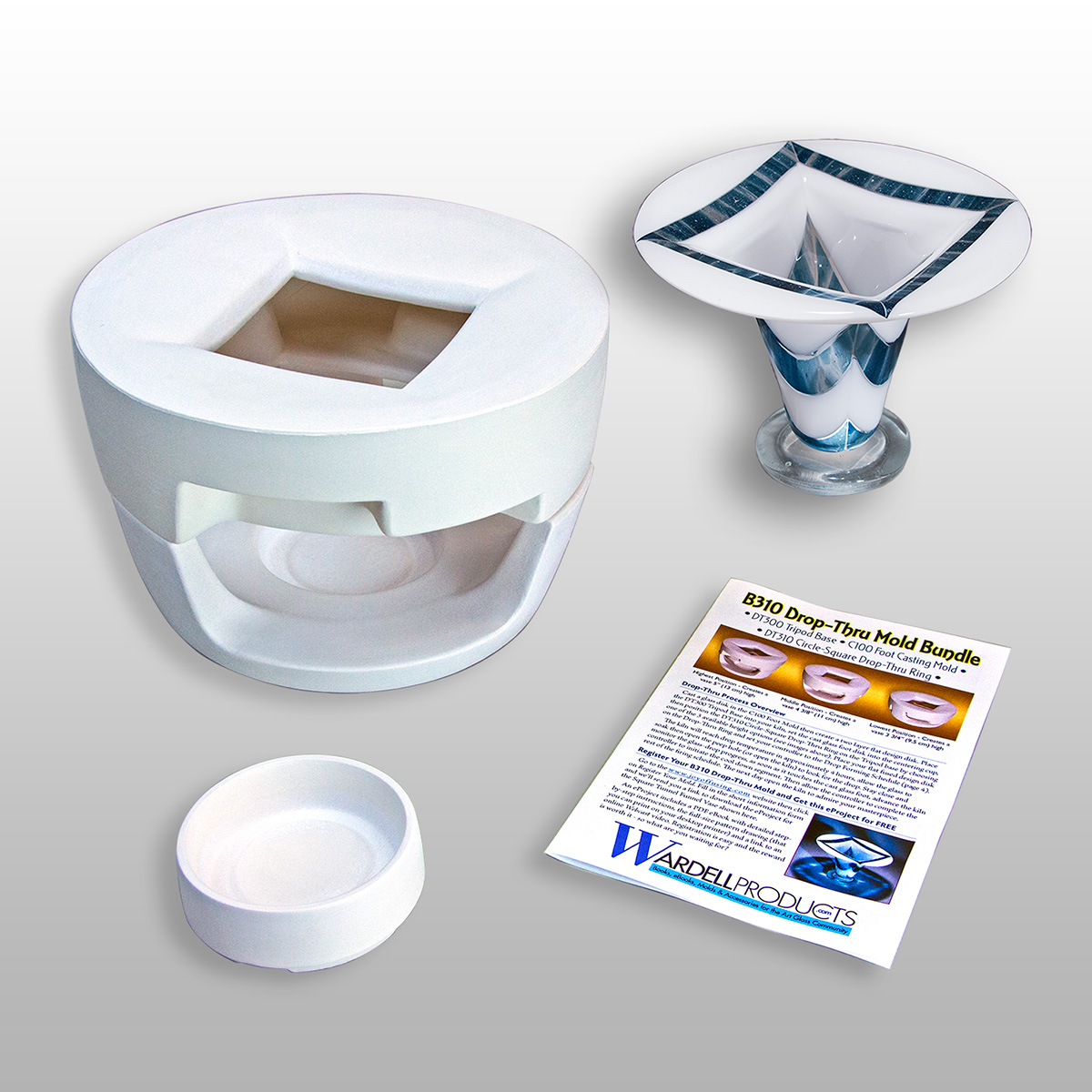

Create a Contemporary Footed Vase using this 3-Piece Drop-Thru Mold

Now fusers can create a Drop-Thru footed vase using this 3-piece mold forming system. Start with a 2 layer circle design that Drops-Thru a square hole in the ring mold then the glass drop is automatically aligned to hit and fuse to the center of a pre-cast glass foot disk.

Download DT310 Product Data Release in PDF Format

Watch this 2 minute video to see how it works.

Drop-Thru Mold System Process Overview

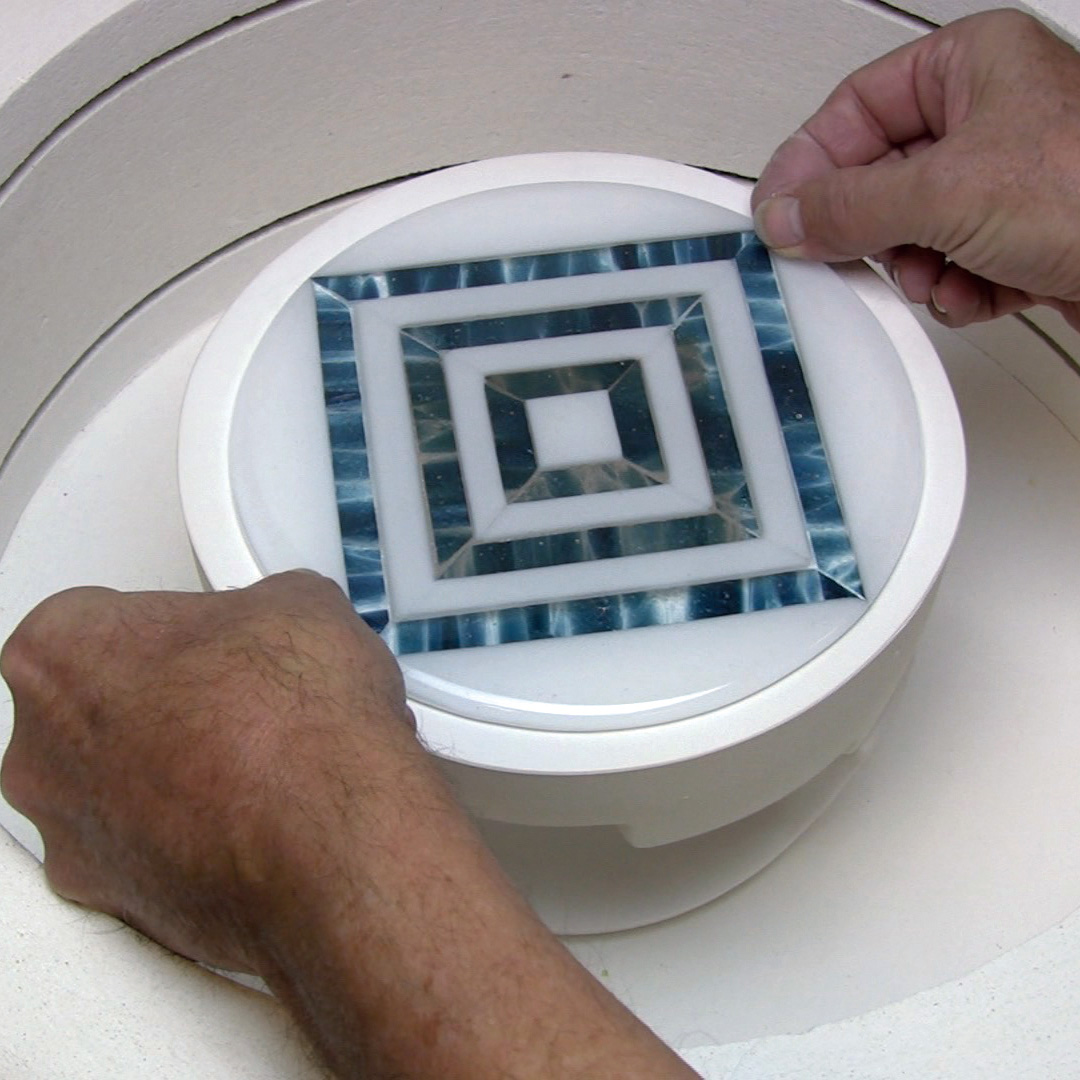

Cast a glass disk in the C100 Foot Mold then create a two layer flat design disk. Place the DT301 Tripod Base into your kiln, set the cast glass foot disk into the centering cup, then position the DT310 Circle-Square Drop-Thru Ring on the Tripod base by choosing one of the 3 available height options (see images above).

Place your flat fused design disk on the Drop-Thru Ring and set your controller to the Drop Forming Schedule included in the instruction booklet. The kiln will reach drop temperature in approximately 4 hours, allow the glass to soak for 20 minutes then open the peep hole (or open the kiln) to look for the drop. Stay close and monitor the glass-drop progress, as soon as it touches the cast glass foot, advance the kiln controller to initiate the cool down segment. Then allow the controller to complete the rest of the firing schedule. The next day open the kiln to admire your masterpiece.

Note: Kiln chamber must be minimum 13” diameter by 6” deep.

Register your Circle-Square Drop-Thru Mold

Click here to register your mold and receive one complete eProject for the Drop-Thru Mold. An eProject includes a PDF eBook with detailed step-by-step instructions, the full-size pattern drawing (that you can print on your desktop printer) and a link to an online Webcast video where you can watch the fabrication process from beginning to end.